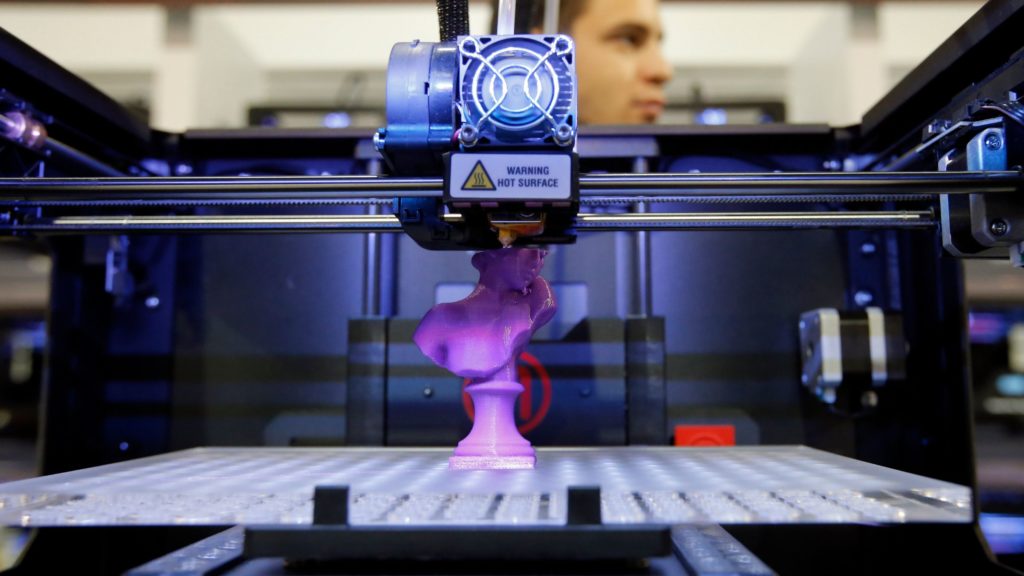

With the rapid growth of the 3D Printing industry, being able to get started making your own prints as a hobbyist or even in a commercial setting has never been as easy as it is today!

When you’re shopping for 3D printers and looking over a bunch of different options, it can be really hard to understand which particular printer would be the best fit for your needs. Apart from a myriad of available models and the different types of printers for various applications, there’s a lot of variables to take into account and keep in mind.

Thankfully as 3D Printing becomes increasingly mainstream, people looking to get started on a budget have quite a few options available to them. From all-in-one beginner kits to advanced special-function printers, the market is on a massive upswing, and it doesn’t look like it’ll be slowing down anytime soon.

So while it’s easy to see where the popularity comes from – how exactly does one choose the best possible printer, especially one that won’t break the bank?

Contents

Best 3D Printer under $1,000 Reviews 2020

Some printers have high price tags but can be difficult to use, or yield prints that require way more post-process work than they’re worth. And as we all know – not all that shines is gold. That’s why we’ve decided to put together an article to give you a clear and concise overview of the 10 best 3D Printers available in today’s day and age, priced under 1,000 dollars.

We’ll help you figure out which printer is the best choice for what you’re looking to do, as well as tell you about every little in-and-out detail that you should keep in mind when making your selection.

So, if you’re ready to get a crash course on 3D Printing and start putting together your short-list of the best printers to look out for – let’s jump right in!

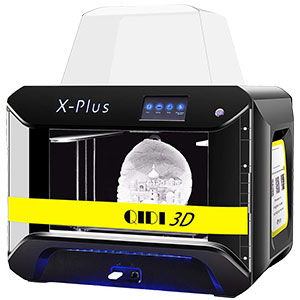

1. The Qidi Tech X Plus

Qidi Technology is one of the pioneers in desktop 3D printing, hailing out of China, and the Tech X-Plus is a model that combines both affordability and amazing versatility. This printer is equipped with insurmountable user-friendliness features and is backed by an incredibly active online community to help you get started with printing and figure out all of the little details along the way. The versatility of Tech X Plus’s ability to handle different filaments and its high-temperature range make for high-quality prints with little effort.

Assembling the Tech X-Plus only takes a handful of minutes, and its instructional manual is very clear, helping you get started on day one. The print bed comes fashioned with a unique double-sided layout, which provides leeway for using a handful of different filaments, while also allowing them to stick better to the build plate.

The main extruder hits temperatures of approximately 260°C, which is great for your standard range of filaments, like PLA, ABS, PETG, or TPU. The secondary extruder runs at hotter temperatures, pushing just south of 300°C, which allows you to use high-temperature filaments such as nylon, carbon fiber, or PC.

The X-Plus also features a stylish closed-frame build that retains heat, reduces fumes, and keeps the printer running quietly at a low 40Db noise-level. The housing also provides a large amount of build space with a finite build-volume of 10.6″ x7.9″ x7.9″, which gives you a lot more play-room over your typical 6-8″ layout printers.

The touch-screen controls on this model screen allow you to easily dial-in settings and connect to Wifi or Ethernet for seamless remote printing capability, and getting the software set up on your computer(s) is practically a breeze. Qidi recommends using their stock slicing software, Cura, which works smoothly with the X-Plus and Pro models; however, it is perfectly compatible with multiple other popular modern slicing software.

Overall, we would say that this is one of the best printers when it comes to the “bang for your buck” factor. It’s perfectly beginner-friendly and yet flexible enough for complex commercial needs.

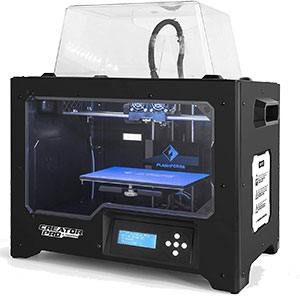

2. FlashForge Creator Pro

Flashforge is a great brand for both beginners and advanced users alike. The Creator Pro is another great option if you’re looking for a flexible 3D printer to cover a diverse range of potential applications. And it comes at a very affordable price tag of only $799.

The Creator Pro can Handle materials such as ABS, PETG, PLA, and PVA out of the box. With a closed-frame design, it’s also perfectly suited for in-home printing due to the low noise levels, and this same design also makes it a great option for high-temperature printing as well. It efficiently cuts out the need for support structures, which also cuts a lot of time out of your post-process work and allows you to print some amazingly complex designs in a fraction of the time you’d expect from other models.

The exterior design includes handles that allow for easy transportation, and the small frame also ensures easy storage, especially in space-challenged environments. When buying, you’ll have the option to pick between a stock power-supply or upgrade your unit to a broadband model instead. However, we should note that the stock PSU is good enough for most applications, and unless you plan to do some serious printing, there’s little reason to tack on the upgrade.

One of the coolest features about the Creator Pro is its patented nozzle with dual-color printing capability. The nozzle comes equipped with two high RPM fans to provide great airflow during the printing process, which improves molding and allows you to print very detailed pieces.

It comes with their in-house brand of software called Flashprint, which adds a lot of ease of use functionality and removes the added cost of an aftermarket software purchase. However, if you feel like their software just doesn’t make the cut – the Creator Pro also works flawlessly with other popular slicing software like Cura, 3D Builder, and Slic3r by default.

This model is definitely a huge step-up from prior models released by Flashforge, and with a 60% increased printing speed – it’s pretty easy to see why the Creator Pro has quickly become one of the most popular affordable 3D Printers on the market.

3. Qidi Tech X-Max

Although the X-Max by Qidi Tech is slightly out of the “below $1,000” price range, it still deserves an honorable mention in our list. This is a very versatile advanced 3D Printer with a very handsome and lucrative set of features. The X-Max is perfect for those looking to upgrade to a more professional machine and can offer a best of all worlds experience to beginners as well. Put simply – when you invest in a semi-professional machine like this, you’re paying for quality. And with the X-Max, quality is exactly what you’ll be getting.

The features of the X-Max are actually quite similar to the X-Plus, with a few key modifications to its hardware that make this printer a strong condender against the other models on this list. One of it’s most interesting features is the magnetic removable build plate, which is designed to operate at a wide range of temperatures and is double-sided like the X-Plus. It’s also flexible, making it incredibly easy to remove models from the plate after a successful print.

The closed build and its high-temperature capabilities mean that just like with the X-Plus, the X-Max allows users to print with a very large variety of different filaments, from PC and nylon to ABS and the more flexible filaments like TPU.

In terms of build volume, we’re looking at 11.8″ x.9.8″ x11.8″, which makes this printer substantially larger than most of the models on our top 10 list. This means that the X-Max is a great budget-friendly option for those looking to step into the realm of high build-volume printing.

Qidi has shown that helping customers get the best bang for their buck is on the top of their list of priorities, and customers who’ve purchased this model can enjoy a new and improved air purifier. This air purifier significantly reduces both the fumes and odor of the printing process, while providing the necessary cooling capacity to improve molding and ultimately guarantee a fine level of detail in your prints.

So, if you’re getting into more advanced printing, or simply need the above-average build volume that the X-Max offers, this printer by Qidi Tech definitely deserves a spot on your short-list.

4. The Bibo 2

The Bibo 2 is unique in comparison to other 3D printers on our list due to the fact that it comes with laser engraving capability alongside a versatile 3D printing arsenal for users to enjoy.

Other notable features include dual cooling fans (similar to what you’d find in the Creator Pro by Flashforge) and power-loss sensors that stop feeding the filament if you lose power. This model also ships with powerful dual extruders that really open up the range of possibilities of this wonderful printer.

The laser that’s shipped with the Bibo 2 seems to handle a few different types of plastic, wood, paper, and cardboard very well. And while it’s not a perfect laser engraving tool, it’s definitely a nice addition to the already powerful kit that this printer packs.

One of the things that we were the most excited about had to do with an issue that’s been plaguing the 3D Printing industry for a long while. That is – having to start your print over if the power goes out for any reason. Keep in mind, 3D Printers use up quite a bit of power, so it’s not unusual to see spikes and rare outages due to blown fuses here and there. The Bibo 2 was intelligently designed to pause and resume printing if there’s any kind of disruption. If for some reason you run out of filament, the printer will also pause and allow you to re-load the necessary filament before resuming the work at your discretion.

Temperature regulation is another important feature in just about any printer. The Bibo 2 addresses temperature regulation through a pair of dual cooling fans that can easily be adjusted through its touch screen interface, or even through a wifi connected device.

And when you consider it’s incredibly affordable $690 price tag – the Bibo 2 is definitely a solid contender for being one of the most versatile printers that you can buy on a budget.

5. Dremel Digilab 3D20

In the world of DIY and hobbyist goods – Dremel is practically a household name!

And ever since their DigiLab division was rolled out within their active lineup of products – they’d graced the world with a fairly successful lineup of affordable 3D Printers. The majority of printers, including the 3D20, are geared towards educational clientele alongside hobbyists and tinkerers looking to bring their designs to life from the comfort of their own home.

There are two very important things that make this printer a great option for people who are only taking their first steps into the 3D printing world. Firstly, it’s ready to print out of the box, with next to zero setup effort required on your end. Additionally, it’s an enclosed design, which makes it a much more home-friendly option due to the noise reduction, while keeping it practically mess-free as well.

One thing that Dremel does differently from other manufacturers is that they really lean on their education focus as a company hallmark. With every printer in their Dreamlab lineup, they actually include informative and easy to follow lesson plans. This is amazing for schools and parents alike as you’ll be able to get your kids (or students) totally engrossed by the activity, and help them get started with 3D Printing in no time at all.

But as with all good things, there are a few potential downsides to the 3D20. One of these downsides has to do with the fact that it doesn’t have a heated bed – which means you’re limited to only printing with PLA. And overtop of this, the filament spool is actually a fairly odd size, being roughly one fourth the size of a traditional spool. This more or less locks you into buying filament directly from them.

But, if these aren’t major deterrents for you and you’re looking for a decent all-around printer at a relatively affordable price – this may be an option to consider. However, our opinion is that it’s relatively bland in terms of its feature offering by comparison to other printers around the same price, such as the Qidi Tech X Plus.

6. Monoprice Voxel

The Monoprice Voxel is one of the more affordable 3D printers on our list, that features a surprisingly high print quality considering its $429 price tag. The stock software and firmware for the Voxel seemed to be a little rough at launch, so it may take a bit of tweaking to perfect the outcome of your prints. Aside from this minor setback, it’s incredibly easy to use, being a complete plug-and-play solution.

The Voxel features a lightweight design that makes it great for printing at home. For such a small build, it’s able to handle a rather impressive print volume of up to 6.9″ on each side, which makes it pretty versatile in that it’s able to bring a very wide array of different designs to life.

For this model, we’re looking at another enclosed design with a heated print base that’s flexible, just like the base you’d find in the more expensive Qidi printers. This means you’ll have an easy time removing the prints from the base, and it can also help you get away with thinner supporting structures, allowing for a pretty impressive level of detail.

In terms of controls – the Voxel comes with a pretty standard LCD screen and control panel, where you’ll be able to dial in your settings and configure a connection to the cloud for remote printing. The Voxel also sports a camera that allows you to view your print in progress as well as a nice automatic filament loader.

All in all, the Voxel is a pretty good 3D printer for beginners – despite the bit of tinkering required to yield a high-quality print. The long list of user-friendly features and it’s all-around solid build-quality makes this printer an especially cool entry-level option. And while it’s a little bit on the expensive side as an entry-level printer, it’s far more versatile than other members of that same category.

7. WanHao Duplicator 7 Plus

The Wanhao Duplicator 7 Plus is a resin printer that provides amazingly accurate details on incredibly small-scale prints. In fact, this printer is renowned for its accuracy at XY sizes as small as 0.0001mm.

One notable feature that stands out right away is its lightning-fast printing speed, which makes this printer a great option for someone who needs to create a lot of small prints in a short time-span.

We should definitely mention that the Duplicator 7 Plus is by no means a printer for first-timers or beginners in general. This kind of printer is for someone with a bit of experience and some form of prior knowledge of the 3D printing process, as well as an idea of how to handle the chemicals involved in Resin printing.

The native resolution of the Duplicator’s LCD display is a whopping 2560 x 1440, which makes it far easier to use than some comparable models. And inside of the printer, you’ll find a refillable tank for resins, which makes it easy to keep the machine running without any major interruptions between prints. Just make sure the tank is full before starting, as there’s currently no feature to stop and resume work while you refill. Wanhao actually offers a handful of different resins to get you started, but a lot of cheap off the shelf resins will do just fine in the Duplicator 7 as long as they have an active wavelength of 405nm.

With this printer, you’re able to print a large selection of designs with micro-details, such as jewelry, small figurines, and even surgical or dental guides. Its advanced feature kit makes it an ideal DLP printer for companies looking for a budget-friendly option to get started with resin printing.

8. Creality CR-10S

From the Chinese manufacturer Creality, the CR-10S is an incredibly affordable large build-volume 3D printer. Being the second open-frame model on this list, it takes a bit longer for the CR-10S to heat up, and the pieces can sometimes have a bit of trouble sticking to the glass bed, so it may take some extra steps to turn this one into a printing powerhouse.

There are several models of the CR-10S, including the S4, the S5, the Pro, the V2. Consumers also have access to a handful of upgrades when buying, all of which thankfully land in our price range.

Out of box, the CR-10S takes about 30 minutes to assemble and get printing. The power supply and controls are packed into a separate external “brick,” and the spool holder is mounted to the top of the build-frame for an easy and seamless filament feed.

The heated bed reaches a temperature of up to 100 °C, and while it’s not ideal for certain filaments – getting an enclosure for the printer to increase its operating temperature and open up some versatility in terms of material options may be worth looking into. However, the upside to the glass bed is the fact that it’s super easy to get your finished product off the bed without damaging the print, or having lots of cleanup work to do after.

Similar to the Bibo 2, The Creality includes an auto-resume feature, should the power go out, or if you run out of filament while printing. This printer is also backed by an amazingly active team that pushes out frequent firmware updates that bring lots of new functionality to the table, such as auto-adjustment for the leveling bed.

This printer stacks up well against other models in a similar price range and makes for an amazing open-frame alternative to something like the FlashForge Creator Pro.

9. The Elegoo Mars

So far, we’ve only covered one other Resin printer. And the Elegoo Mars is probably the best entry-level Resin printer on the market right now!

It comes packed with a tonne of very simple to use, yet powerful features and a way easier setup process than its counterparts. The Elegoo Mars is also unique in that it’s a 3D printer that utilizes stereolithography to achieve a quieter streamlined printing experience by comparison to something like the Duplicator 7, which is a DLP (Digital Light Projector) printer and is definitely on the noisier side of things.

One of the things that we really enjoyed was the fact that this printer comes fully assembled and ready to use out of the box. At a price point of only $250, that’s very impressive!

And by the way, when we say that it’s quiet – we mean it! After it has dispensed resin into the resin vat, all you can hear is a quiet humming from the shifting build plate. Which is a drastic change from 90% of other printers that can make your home (or workshop) sound like a full-on factory undergoing an operational upturn.

Overall, the Elegoo Mars provides a smooth printing experience because of the lack of troubleshooting involved to get it running properly. With most filament printers, you can expect occasional jams or disruptions to happen every so often. But with this $250 wonder-printer, malfunctions are few and incredibly rare.

The compact design and its use of support-legs provides lots of stability, and you can even get away with moving it gently as it prints without screwing up the whole process. And thanks to the removable lid, it’s also very easy to get the finished product off of the built-plate. This is handy because it helps you avoid the post-print messes that resin printers are known for.

To reduce post-processing time, the stock software that ships with this printer, Chi-Tu, has recently added an anti-aliasing feature that allows for even more smooth and incredibly detailed prints.

Honestly, you almost can’t go wrong with the Elegoo Mars. The price tag alone makes it one of the coolest printers on the market. However, resin printing is still generally geared towards more advanced users, but with how simple this printer makes the whole process – it might just be viable for beginners to pick up and start out on.

10. AnyCubic Photon

We had some trouble deciding where this model was going to end up on our list. The Photon is a pretty much run-of-the-mill DLP resin printer with a low price tag and a small sprinkle of user-friendliness. And just like the Elegoo Mars, this printer comes pre-assembled and works out of box. Just plug it in, adjust the build plate, and watch the magic happen.

Physically, this printer is built with some pretty high-quality industrial-grade materials. The build plate and resin tub are made from machined aluminum, and the frame uses stamped sheet metal. But don’t let the price tag fool you on this one, it’s very sturdy, and the print quality is just as detailed as some of the more expensive resin printers. In fact, the voxelization in the prints is pretty hard to notice, which is pretty surprising for a printer with this sort of price tag.

After you turn the Photon on, you’ll immediately notice it has a profoundly simple LCD touch display. Everything about it is so straightforward that in all honesty, it doesn’t even require an instruction manual to understand what to do and get started.

The slicing software that comes pre-packaged with this printer, aptly named Photon Slicer, is pretty simple to use and contains all the standard bells and whistles that you’d expect. Simplicity is almost a theme when it comes to this model, which makes the Photon a great option for beginners looking to try their hand at printing with resin.

Keep in mind that the whole process may get a little bit messy from time to time, and you may run into small deformities due to occasional issues with the resin peeling. However, we can definitely confirm that they don’t come up often and don’t really take away much from this printer’s usability.

So if you’ve got your heart set on DLP printers and want an easy to use entry-level option – the Photon is a top candidate for the accolade.

Things you should know before selecting a 3D printer

If you’re serious about getting into 3D printing, whether for it’s for personal or commercial purposes – you’ll need to get a solid grasp of all the different options and variables at hand.

This means you’ll need to learn about the differences between technologies used in 3D printing, the steps required to process a print, safety precautions to keep in mind, and the profile of all of the materials that are available for your printers.

To give you a comprehensive run-down, we’ll start by going over the five different types of 3D printing.

The 5 main types of 3D printing

Stereolithography (SLA Printing)

Stereolithographic printers are known for producing incredibly fine details. SLA is one of the types of printing that we would refer to as resin printing. It works by heating the resin into a malleable form, and then slowly building a print layer by layer. The resin then hardens on contact to form your design.

These types of printers utilize an ultraviolet laser as well as X and Y scanning mirrors to ensure extreme precision. Prior to printing each layer, a small “recoater blade” moves across the layer to ensure the resin is distributed evenly across the print. This continues until an entire model has been built from the bottom up.

After the printing process, the finished product would need to be carefully removed from the printer and soaked in a chemical bath to remove any excess resin. An additional curing process of putting the model in a UV oven is also quite common.

If there’s any deformities or buildups after curing the product, you then move on to a post-processing phase of sanding the model and painting it over. SLA is a widely used approach in numerous industries, including the entertainment, automotive, aerospace, and consumer sectors.

DLP(Digital Light Processing)

DLP was the first 3D printing method to be invented and applied in an industrial environment. DLP printers also fall under the resin category, and in a similar fashion to their SLA counterparts, DLP printers utilize light to calculate and form prints.

While SLA uses UV light, the DLP approach uses arc lamps as a light source. It’s actually similar to a camera in the sense that it exposes entire layers at once. SLA has to draw every layer out with a laser, whereas DLP is a similar but much faster approach to resin printing.

DLP printers tend to use cheaper resins, so it’s a great alternative for hobbyist printers looking to get into the craft.

FDM(Fused Deposition Modeling)

FDM printers are a little different than resin printers because they’re able to make use of numerous different plastics and polymers to print 3D objects.

Like any 3D printer, a print model will first be processed using a slicing software. When the sliced model is ready to be printed, the FDM printer heats up its filaments and starts to push them out on to the base, layer by layer.

FDM is practical because of its ability to use different materials together. This makes it easier to add support materials to the model, which then dissolve during the printing process. However, a potential drawback compared to resin printing is that FDM requires a lengthy post-printing process to finalize the prints.

SLS(Selective Laser Sintering) and SLM (Selective Laser Melting)

SLS and SLM utilize lasers to melt down powdered materials. The SLS approach can fuse or melt down metals, nylon, ceramics, and even glass to construct a print.

This approach utilizes a high powered C02 laser to fuse materials together. After which, the printer then follows a process of scanning the build platform and incrementally lowering the platform as it sinters materials together in the programmed design. This type of printing is practical in an industrial setting to accurately create parts and miniature products.

SLM also uses the heat of a laser to melt material into a layered structure. It’s somewhat comparable to FDM printing in the sense that it melts down materials, which is practical for creating products that require complex and durable designs.

Now that we’ve looked at the most common printing techniques and types of printers – let’s dive into the materials that you’ll need to start bringing your creations to life.

An overview of the most common 3D printing materials

PLA

Polylactic acid is a byproduct of cornstarch that works well as a material for beginners. It’s great for creating small and simple prints that don’t require a lot of detail. And if you care about going green, due to its plant-based makeup, it’s also biodegradable.

When melted, PLA cools very quickly, which restricts any possibility of warping and makes your prints fairly durable. PLA is also available in a large variety of both solid and see-through colors, all of which add a cool glossy look to your finished product.

However, despite it cooling very quickly, under higher temperatures, PLA may end up bending or warping, so opting for a 3D printer with built-in fans or an open bodied model may be a good idea if you plan to work with this material.

ABS

ABS is a hard petroleum-based plastic often found in computer parts, car parts, medical supplies, and our favorite constructor toys – Lego bricks.

This material works incredibly well under high heat. And because of its flexibility and durability, you can easily create complicated interlocking pieces.

PET

Polyethylene Terephthalate is a soft polymer plastic found in water bottles and even some polyester clothing. PET is safe to use with food and water, which makes it great for printing utensils, containers, and practically anything where the material being food-safe is an important factor.

It’s also a recyclable material, which makes it a good option for those who are environmentally-conscious.

Nylon

Nylon is a super durable material often found in sleeping bags, rope, seat belts, parachutes or even dental floss and toothbrush bristles. When melted down and cooled into a solid substance, it becomes incredibly durable, allowing you to add a significant bit of durability to your creations without needing rigid and thick support structures.

Though, it does require very high temperatures to melt, so make sure your printer supports the temperature range necessary before buying.

TPU

Thermoplastic polyurethane is one of the most common plastics that you probably see on a daily basis. It’s used in everything from cars to shoes, sports equipment, cell phones, and durable textiles. The uses for TPU are almost endless.

It’s a pretty popular filament in 3D printing, but it’s also worth bearing in mind that it may be difficult to work with it in the post-processing phase, making it not quite the best fit for casual printing purposes.

Polycarbonate

PC, or polycarbonate, is the strongest thermoplastic you can work with. It’s commonly found in electronic devices. But PC is also used in construction materials, CD’s and DVD’s, aircraft, and trains due to how amazingly durable it is.

Surprisingly, despite its ruggedness and durability, this is one of the easiest materials to work with in the post-processing phase. This makes it a great option for building designs that require a high degree of durability, especially in the wide variety of potential industrial applications.

Which polymer should I use as a beginner?

Generally, PLA and ABS are a great way to dive into the world of FDM printing. But as a rule of thumb – the material that works best for you will really depend on the design of the product you’re trying to bring to life.

You may need to do a bit of in-depth research and planning to figure out which one to opt for. Thankfully, with how quickly 3D printing is growing, there are plenty of online communities that contain all the necessary information to help you decide on the right filament for your printing needs.

But regardless of the filament you use, there’s a number of things to watch out for to keep your 3D printing experience fun and totally safe.

Safety tips for 3D printing

Heat

When you’re 3D printing, you’re heating up plastics and other materials to temperatures that could lead to some incredibly nasty burns. The extruders, the print beds, and the filaments themselves may be hot when you’re handling your printer.

You may want to pick up a pair of heat resistant gloves at your local hardware store to protect your hands. And better yet, try to not fiddle with the printer while it’s hot, unless you need to make some emergency adjustments.

Fumes

Thermoplastics emit fumes that can be overwhelmingly smelly, and possibly harmful in some cases. ABS and PLA are known to emit UFPs (ultrafine particles), which could potentially lead to respiratory issues if you don’t protect yourself.

We strongly advise that you wear protective equipment and print in a well-ventilated area to avoid any mishaps and potential health concerns down the line.

Food Grade Plastics

While certain plastics are food-safe, you may need to take some extra steps you if you plan on making kitchen utensils. Some of these plastics may contain additives that require them to be coated before being put to use.

Bear in mind that 3D printed objects are also micro-porous and may trap bacteria as they are hard to clean. This is why many people choose to sand the finished product and apply an acrylic coating during the post-production process.

Post-processing techniques and tips

Support removal

If you end up creating models that utilize support materials, there may take a bit of work involved to remove them. Soluble materials are designed to break down in water or in certain chemicals, while some insoluble materials need to be physically cut off.

Sanding

Sanding is the most common post-processing step. This process requires a range of different sandpaper, starting with low grits to remove rough spots, followed by higher grits to smoothen the entire model.

Acetone Smoothing

Acetone, commonly referred to as a paint thinner (and nail polish remover), has the ability to gently melt plastics, which also provides a really smooth and glossy finish for your model.

Unfortunately, using acetone only works with ABS and requires around-the-clock supervision as well as a lot of ventilation. This makes it better suited for industrial applications when compared to a print-at-home setup.

Priming and Painting

Following some gentle sanding, you may want to prime and paint your product to achieve something that’s really aesthetically pleasing. Giving it a coat of paint allows you to add a new level of detail and a whole new character to your model.

This can be a difficult process, but it offers an amazing artistic outlet and helps you add the finishing touches to produce something really great!

Polishing

While it’s a pretty similar process to sanding, polishing works well when you’re making use of more rigid and sturdy filaments to really bring out the level of detail – especially for smaller prints.

You can find a hand-held dremel at your local hardware store, and after sanding your model down, you can polish it up to give it some shine and a whole new look altogether.

Frequently asked questions about 3D printing

Which 3D printer under $1000 is the best for beginners?

A: Either #1 or #2 on the list would be ideal. The Qidi Tech X-Plus and the Flashforge Creator Pro are user-friendly and easy to start learning with.

Can you make money with a 3D printer?

A: If you’re able to design cost-effective prints and sell them for more than the cost of materials and labor, why not?

Is it worth buying a 3D printer in 2020?

A: 3D printing is a rapidly growing industry that’s become more affordable and approachable for the everyday person over the last few years. 2020 Will likely yield a whole new generation of affordable printers and new technologies to go with them, making it a great time to begin your adventure.

Is 3D printing expensive?

A: The cost of 3D printing varies largely based on what you’re trying to accomplish. Some materials and printers are cheap, while others require a significant financial investment to get started and sustain over time.

Can 3D printers print metal?

A: SLM printers can use lasers to melt metal into a workable material in a process similar to printing with thermoplastic filaments.

What materials can be 3D printed?

A: Depending on which kind of 3D printer you have, you can print with close to nine different thermoplastics and a long list of polymers. You can even print with metals if you opt for an SLM printer and resins if you have the appropriate type of printer for those.

Can you 3D print jewelry?

A: Of course! We recommend doing so with an FDM or DLP resin printer as it allows for a greater level of detail. However, if you’re going for metallic jewelry, an SLM printer would be the one you’re after.

What are the disadvantages of 3D printing?

A: 3D Printers generally consume quite a bit of energy and can cost quite a bit to operate based on your material selection and how much printing you’re planning on doing. In addition to this, they’re fairly noisy, and open-frame builds can generate fumes from the melted-down filament. And if you’re considering 3D printing for commercial applications, it’s always best to get quotes from manufacturing firms ahead of time to be able to evaluate whether or not it would be a cost-effective option. Given that most of these companies already have a manufacturing infrastructure in place – you would otherwise be building your own from the ground up, which can quickly skyrocket the cost of 3D printing.

Can you 3D print food?

A: Yes, food can actually be 3D printed by using a specially made 3D printer. While none of the printers on our list are able to do this, the ones you should check out are Foodform3D and the Chefjet.

Which material is better PLA or ABS?

A: Both materials work really well! Which material is best would depend entirely on what you’re trying to print.

How long does it take to 3D print something?

A: The time required to 3D print something depends on the size and the level of detail of the object. Which kind of printer you’re using also has an important role to play as different printers feature different printing speeds. The entire process can take anywhere between 10 minutes and several days.

Closing Thoughts

From printing as a hobbyist to doing it for your business, the art of 3D printing is incredibly fascinating and has become more affordable than ever in recent years.

It can be a difficult task to get started and set everything up, but it’s grown in popularity because it’s an enjoyable process that yields practically anything that your mind is able to envision.

However, picking out the right printer is definitely no easy job, especially for those of us who want to get printing without breaking the bank. We hope that our all-you-can-read guide to the 10 best 3D printers under $1,000 gave you some new ideas and potentially even a few candidates to add to your shopping list.

Comments 12