3D printing is the future of manufacturing. Many industries have already taken advantage of it. Even the Engineers in the aerospace or the companies involved in the automotive and healthcare industries know the potential of it. 3D printing is a fast prototyping method that also has many economic benefits.

This technology can print parts that can go in race cars, airplane interiors, medical devices and has much more use cases. Even those who don’t have access to a best 3d printer under 1000 can avail the advantage of it. There are many printing services that allow other companies to outsource their needs by just giving them the design or 3D model.

The benefits of 3D printing cannot be ignored. It does a lot of things better than the traditional manufacturing methods which involved molding and subtractive methods. This technology enables us to create a product with more complex designs.

We have freedom of customization. We can also use materials that are lightweight and much more advanced. The possibilities are endless so, in this article let’s talk about some of the uses of 3D printer which are already in use and are replacing the traditional manufacturing process. So, without wasting more time, let’s dive in.

What is 3D Printing?

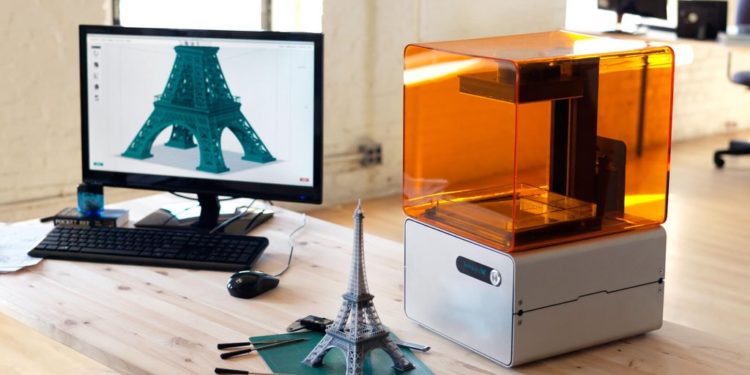

There are a number of different types of additive manufacturing processes and are already in use in many industries. They either use plastic, resin, and many other materials. Although the most popular one is 3D Printing. 3D printing is one of the additive manufacturing processes that create three-dimensional products by adding materials layer by layer on top of each other until the product is complete.

This process is achieved using a machine called a 3D printer, it is a very simple machine which takes a digital file for the 3D model, it can be created using any CAD software. Now a suitable filament is used for the object and then the printer takes over. The machine then turns it into a 3D object using the additive manufacturing process. This is how the 3D printing process goes.

3D printing has much more potential in the future. This method is opposite to the traditional subtractive method where the product is created by molding and removing the extra pieces from the raw material. It is also cheaper and provides great flexibility and this is because nowadays most of the manufacturers are moving toward 3D printing.

What is 3D Printing Used For?

As said before, 3D printing has already been in use in many different industries. Now let’s talk about some of the most popular ones.

Rapid Prototyping

The use of 3D Printing technology basically started with the production of prototypes of the designs of the actual product to show the clients or the customer before the production begins. It has a huge number of advantages to talk about.

We can still evaluate the design while it is still in progress, once the designing is done, a 3D prototype can be made which can be touched and feel. Finally, we can also compare the 3D model to the other components and see if it fits and function properly.

Apart from this one can easily compare the printed product and the 3D model side by side and if there are any changes the new iteration can be printed again at a much faster rate.

This saves a lot of time in production. Again, these prototypes don’t need to be made of actual material like the final product instead we can easily use materials such as plastic or resin to test out the prototype.

Direct Digital Fabrication

Not just prototyping but 3D printing can be used to create actual final products as well. It can help create serial numbers, marketing designs, interlocking, and joint structures which can be included in the physical structure of the product. This doesn’t even require any extra tooling step other than 3D printing.

There are various structures called one-off which is used in racing cars, medical equipment, and space technologies. These are very costly in terms of production because with the traditional manufacturing process the mold or tool can be used only a few times. Here 3D printing brings down the cost of production and allows mass manufacturing of the goods.

It also allows us to make instant updates right in the middle of the production cycle without the need for retooling the production line. This feature of 3D printing made its way into the production of future aircraft engines where updates can be performed to save a lot of time in the production of high precision engine components.

Restoration and Repair

3D printing can obviously help in creating a new object but at the same time, it can also help in re-creating an object which was once available a long time ago and is not in production anymore. The component can be anything and can be made with any material as long as the 3D model of the same is perfectly made. This can help in the restoration and repair of antique items to their original condition. You can make an unlimited number of modifications within the computer before creating the part. This eliminates the need for storing each and every component in the warehouse instead of that we can simply pick the right design and print out the part whenever needed.

Can 3D printing live up to the hype?

3D printing is the future of manufacturing, imagine being able to go online and buy almost anything you can think of and get it delivered to you the next day at your doorstep. You can make an unlimited number of modifications and design the object as per your personal preference and specifications.

More and more companies like Amazon are constantly investing in 3D printing technologies for their upcoming products. The day is not far when we will be using most of the products which are 3D printed and have their own 3D printer at their home to print whatever product they want to.

To fully harness the advantage of 3D printing one must understand its capabilities and that’s the point of this article. Hopefully, after reading, you are fully aware of the technology and its potential to change the future.