Gone are the days of noisy, dangerous, and challenging welding machines. With the advent of welding robots, your business can now benefit from high-quality welds with minimal operator input. Here are four reasons you should consider a welding robot for your next project.

The benefits of welding robots for businesses

A welding robot offers several benefits for businesses. First, they can help to improve the quality of welds. By using robotic welders, businesses can ensure that each weld is consistent and meets the highest standards.

Additionally, welding robots can help to boost productivity. Because they can work faster and more efficiently than human welders, businesses can complete projects in a shorter time frame. In addition, welding robots can help to improve safety in the workplace. Businesses can reduce the risk of accidents and injuries by removing the need for human workers to be in close proximity to welding equipment.

As a result, welding robots can provide some advantages for businesses.

How welding robots can improve your bottom line

The welding process has come a long way since it was first introduced in the early 1800s. Today, welding is an essential manufacturing process that is used in a wide range of industries, from auto manufacturing to shipbuilding.

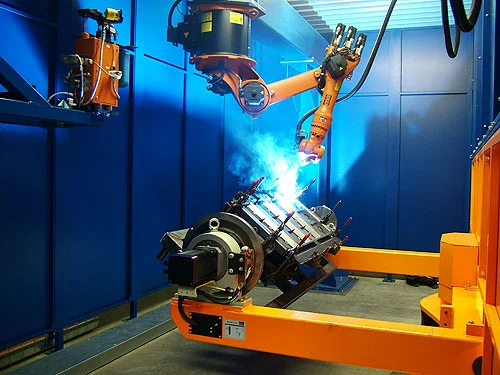

One of the most significant advances in welding technology is the development of welding robots. These automated machines can perform a variety of weld types with greater precision and speed than human workers. As a result, they can help to improve your bottom line by increasing productivity and reducing manufacturing costs.

In addition, welding robots can help to improve product quality and reduce scrap rates. As the demand for higher-quality products continues to grow, investing in welding robots is essential to stay competitive.

The many applications of welding robots

Welding robots are increasingly used in various industries due to their many advantages. For example, welding robots can work in difficult-to-reach places and do not require breaks like human workers. In addition, welding robots can work for longer hours without getting tired and can be programmed to repeat the same task repeatedly with great precision. This makes them ideal for projects that require a high degree of accuracy, such as in the automotive industry.

Moreover, welding robots are much less likely to make mistakes than human workers, reducing production costs. As a result, it is not surprising that welding robots are becoming increasingly popular in many different industries.

Types of welding robots available on the market

Various welding robots are available on the market, each designed for a specific type of welding application. The most common type of welding robot is the GMAW, or gas metal arc welding robot. These robots are typically used for welding mild steel and aluminium.

Another common type of welding robot is the GTAW, or gas tungsten arc welding robot. These robots are typically used for welding stainless steel and titanium. In addition, there are also robots designed for specific tasks such as spot welding and seam welding. As technology continues to evolve, new types of welding robots are being developed to meet the industry’s ever-changing needs.

FAQs about applications of welding robots

Welding robots are becoming increasingly common in manufacturing, offering many advantages over traditional welding methods. However, there are still some misconceptions about welding robots and their applications.

Here are some frequently asked questions about welding robots to help clear things up:

1. What types of materials can welding robots work with?

Welding robots can work with various materials, including metals, plastics, and composites.

2. How accurate are welding robots?

Welding robots are highly accurate and can often produce welds that are stronger and more consistent than those produced by human welders.

3. How much does a welding robot cost?

Generally speaking, the cost of a welding robot depends on the size and capabilities of the machine. However, welding robots are more expensive than traditional welding equipment.

4. How long does it take to set up a welding robot?

It usually takes several hours to set up a welding robot, although the exact time will vary depending on the complexity of the machine. Once set up, however, a welding robot can typically operate for long periods without needing to be serviced.

Things to consider when purchasing a welding robot for your business

When purchasing a welding robot for your business, there are several factors you will need to consider to choose the suitable machine for your needs:

- You will need to determine the type of welding you will be using the robot for. There are many different types of welding, and each requires different equipment. For example, if you plan on welding aluminium, you will need a machine specifically designed for that type of metal.

- You will need to consider the size of the area you will be welding in. If you have ample space, you will need a machine that can reach all areas.

- You will also need to consider the price of the welding robot. While there are many different models available, the price can vary significantly. Be sure to get quotes from multiple companies before making your final decision. By taking all of these factors into consideration, you can be sure to choose the right welding robot for your business.

Final thoughts

A welding robot can help a business with producing consistent, high-quality goods, in a short amount of time. If you are looking for a consistent welder that has excellent quality welds and can save you time, then a welding robot may be the right choice for your business.