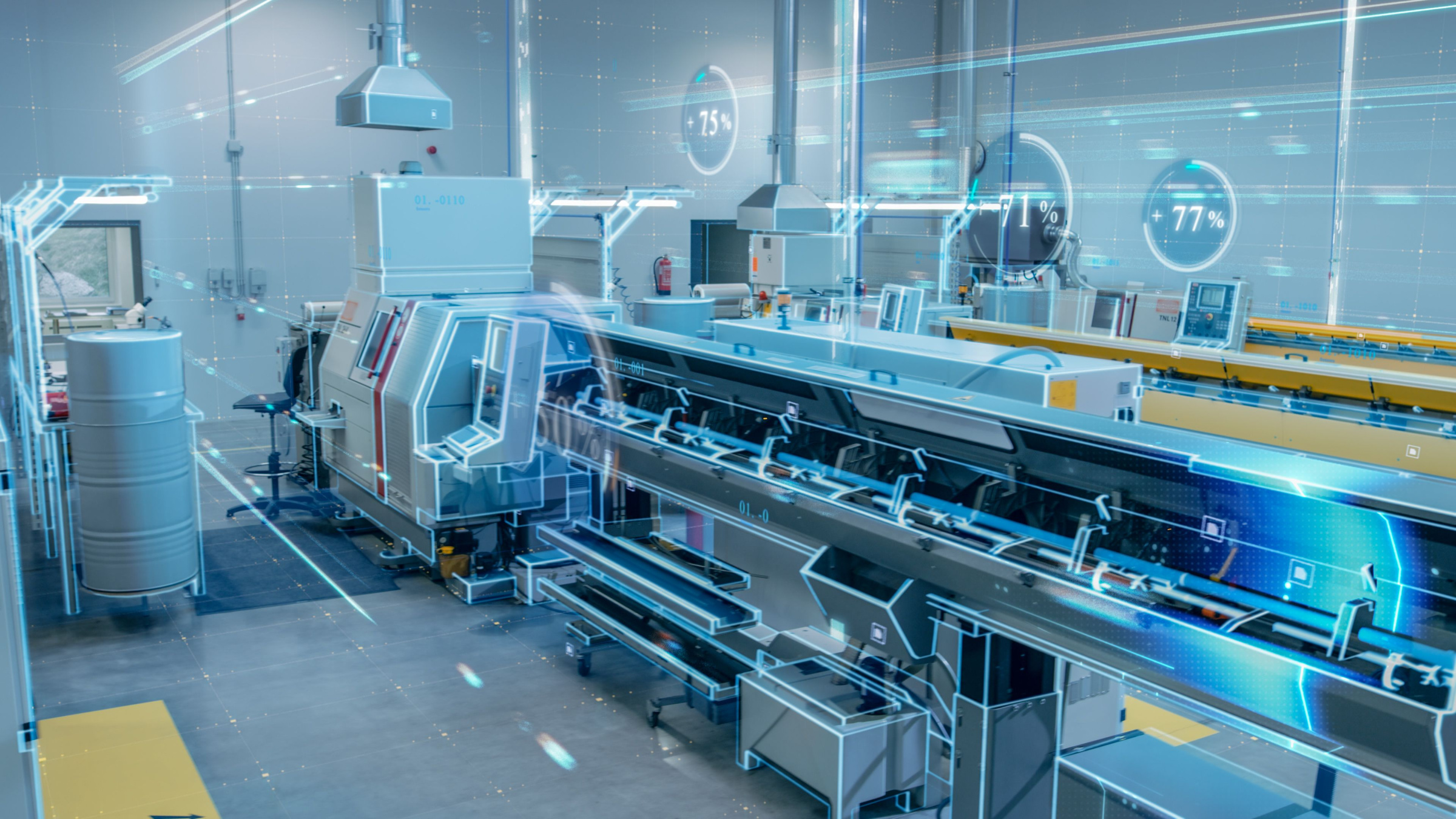

In the realm of manufacturing, efficiency is king. The capacity to manufacture top-notch components swiftly and precisely can be the determining factor that can make or break a company’s success. In recent years, one technology has been at the forefront of this efficiency revolution: CNC machining.

What is CNC Machining?

CNC stands for Computer Numerical Control. In essence, it’s a production method in which pre-set computer software directs the motion of machinery and tools.This means that instead of manually operating machines, everything is automated and controlled with precise digital instructions.

CNC stands for Computer Numerical Control. In essence, it’s a production method in which pre-set computer software directs the motion of machinery and tools.This means that instead of manually operating machines, everything is automated and controlled with precise digital instructions.

The Rise of CNC Machining

CNC machining has been around since the 1950s, but it’s only in recent years that it’s truly come into its own. Advances in computer technology have made CNC machines more powerful, versatile, and affordable than ever before. Enter Dainsta, a company that excels in providing CNC machining services, positioning itself at the forefront of innovation and productivity in the manufacturing industry.

The Benefits of CNC Machining

So, why all the hype? Well, CNC machining offers a whole host of benefits that traditional manufacturing methods simply can’t match. Let’s break them down:

So, why all the hype? Well, CNC machining offers a whole host of benefits that traditional manufacturing methods simply can’t match. Let’s break them down:

Precision: CNC machines are incredibly precise, capable of producing parts with accuracy measured in microns. This level of precision ensures that every part is identical, leading to higher quality and fewer defects.

Speed: With traditional manufacturing methods, producing complex parts can be a time-consuming process. CNC machining, on the other hand, can churn out parts at breakneck speed, significantly reducing lead times.

Flexibility: One of the biggest advantages of CNC machining is its flexibility. Unlike traditional manufacturing methods, which require expensive tooling and setup, CNC machines can be quickly reprogrammed to produce different parts. This makes them ideal for small-batch production and rapid prototyping.

Cost-Effectiveness: Although the upfront investment in CNC machinery may be significant, the undeniable truth is that it leads to substantial cost savings in the long run. By reducing labor costs, minimizing material waste, and increasing productivity, CNC machining offers an excellent return on investment.

Complexity and Innovation: CNC machining enables manufacturers to push the boundaries of innovation by handling intricate designs with ease. This fosters the creation of complex components that drive product innovation across industries.

Sustainability and Material Efficiency: Optimized tool paths and minimized material waste contribute to resource efficiency, promoting environmental sustainability. CNC machining’s compatibility with recycled or eco-friendly materials further reduces its ecological footprint.

Integration with AI and Data Analytics: The integration of CNC machining with AI and data analytics enables predictive and adaptive manufacturing. Real-time data analytics and AI algorithms optimize processes, reduce downtime, and empower data-driven decision-making for continuous improvement.

Customization and Personalization: CNC machining facilitates customization and personalization, meeting the demand for bespoke solutions tailored to individual preferences. From custom automotive parts to personalized medical devices, CNC technology empowers manufacturers to deliver unique products.

Global Connectivity and Distributed Manufacturing: CNC technology facilitates global connectivity and distributed manufacturing networks, enabling efficient resource utilization and agile response to market dynamics across geographical boundaries.

Skills Development and Workforce Empowerment: CNC machining creates opportunities for skills development and workforce empowerment. Aspiring technicians gain hands-on experience, while user-friendly interfaces make manufacturing more accessible, fostering inclusivity and diversity.

Resilience and Supply Chain Optimization: CNC machining enhances supply chain resilience by decentralizing production and reducing reliance on centralized hubs. This mitigates risks associated with disruptions and ensures continuity in the face of challenges.

The Future of Manufacturing

As technology continues to advance, the future of manufacturing looks brighter than ever. From 3D printing to robotics, new innovations are constantly reshaping the way we make things. However, one thing is clear: CNC machining will remain a cornerstone of modern manufacturing for years to come.

Conclusion

In conclusion, CNC machining is revolutionizing the manufacturing industry, offering unprecedented levels of precision, speed, and flexibility. By harnessing the power of computer technology, manufacturers can produce high-quality parts faster and more cost-effectively than ever before.

As we look to the future, it’s clear that CNC machining will continue to play a central role in shaping the world around us, driving innovation, sustainability, and resilience in manufacturing.