3D printing technology is not new and has been in existence for a long time. It was invented by Chuck Hull back in the 1980s and since then we have seen a lot of improvements in this technology. Back in the days, it was very expensive which made it limited to a certain number of people.

It has gained a lot of popularity in the past few years and because of that, it has become much affordable and now anyone can get their hands on a affordable 3D printer. The 3D printer has a lot of advantages over the traditional subtractive manufacturing process such as efficiency and reduction in cost and time for production.

S, if you are into 3D printing then you might often come across a part called extruder which is a component of 3D printer and plays a major role in this additive manufacturing process. In this article, we are going to talk about the extruder, their types, and features and till the end of the article, you will know everything about it!

What is an Extruder

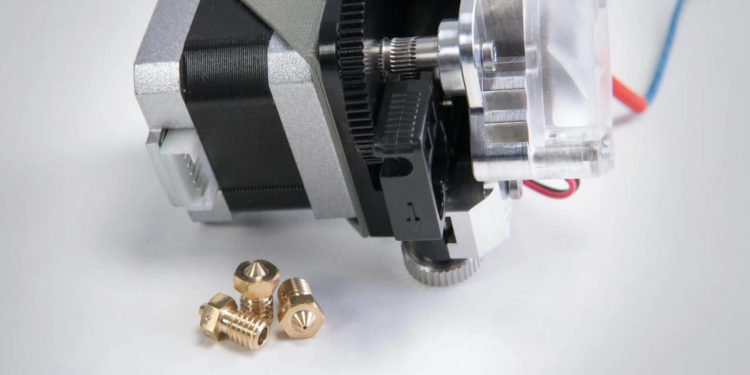

The Extruder is considered as a very essential component of the 3D printer. This is the component responsible for the drawing, melting and pushing the filament out of the 3D printer. Basically, it is the part of the 3D printer where the material/filament is ejected in liquid or semi-liquid form. It deposits the filament in successive layers one by one on top of each other in a specific volume. It is also called a fancy hot glue gun. However, in some cases, it is used to deposit a bonding agent to solidify the material which is originally in the powder form.

Types of Extruder

There are two different types of extruders depending upon the drive. These are Direct extruder and Bowden extruder. Either of these extruders is selected however there is even system where these two extruders are used together. Let’s learn more about them.

Direct Extruder

In direct extruders, both the hot ends and cold ends are attached together so the filament goes down through the cold end and then into the hot end. One of the main advantages of this extruder is it produces clear prints and offers less stringing and oozing. It has a very short distance between the drive mechanism and the hot end which results in printing with flexible materials much easier. These are also more responsive to extrusion and retraction however there are some disadvantages as well. Because the direct extruder is attached to the hot end it might cause the mass to backlash or overshoot sometimes.

Bowden Extruder

The next one is Bowden Extruder, in this one the hot end and the cold end are not directly attached to each other. In this case, there is a tube that extends from the extruder and goes to the hot end. The main advantage of this setup is that the printer will be able to print faster and with more accuracy and precision as compared to the 3D printer with a direct extruder. However, just like the other one, this one also has some disadvantages such as the lag of system and it is also prone to retraction and stringing.

Elements of an Extruder

The extruder is made up of two main elements They are the hot end and the cold end. The cold end is basically the upper part of the 3D printer where you fill the filament/material while the hot end is referred to the component where the filament is melted and pushed out.

Cold end

The cold end is used in the 3D printer to hold the filament and PTFE tubing which then guides the filament. It is made up of stepper motors, toothed gearings, bolts or gears, and spring-loaded idler. So, in the cold end, the stepper motor which is basically a brushless DC motor drives the motion which results in the extrusion of the filament in most of the 3D printers. It also offers high precision because it works with small movements and imparts full torque at a low speed.

Hot end

The hot end is the part where the filaments come out from the other end. Here the filament is passed into a heated chamber where it changes its state from solid to liquid. In the 3D printing process, the filament travels from the cold end to the hot end and then it finally meets the nozzle and this is exactly where the material liquifies. The nozzle is actually the part of the hot end and it is very integral. It is shrewd into the hot end block and they are also interchangeable. You can also buy them in different sizes.

Extruder-related problems in 3D printers

There are several problems you might encounter with the 3D printer extruder. It is very similar to what we have seen with the inkjet printers. It is usually caused due to the poor maintenance of the printer or the use of wrong or incompatible filaments which eventually leads to fouling of the nozzle.

In most of the cases, there are two particular problems, these are Under-extrusion and Over-extrusion.

The Under-extrusion occurs when the printer is not able to extrude the correct amount of filament in some cases. As a result, the printer misses some layers or causes little holes or dots in the layer. This makes the design unusable because the quality of the print is not up to the mark.

The over extrusion happens when the 3D printer extrudes more materials that it is needed and results in dimensional inaccuracy. It might also cause some layers to drop. Apart from this, you may also see stringing and oozing. This will ruin the overall 3D print and make it unusable.

Conclusion

The extruder is a very basic thing when it comes to learning about the different components of the 3D printer. If you are a beginner who just started out using the 3D printer then the extruder is very important since it is the part where the actual 3D printing happens.

If you are trying out new things with 3D printing and want to ask then don’t forget to leave your query or suggestions below so we can check them out and offer some help.