Before going further with the information related to Through Bore Slip Ring, it would be quite beneficial to get familiar with the term slip ring first. Every automotive motor includes a device that allows transmission of power and electrical signals through it. This device is usually termed as a slip ring. These are electromagnetic devices whose one end is connected to the stationary source whereas the other one is associated with the rotating one. The one end of the slip ring goes on rotating consistently further allowing power and electrical signals to pass through it.

Slip rings are one of the essential parts of the electromechanical system that does not include any self-rotation but enables the rotation of the other products associated with it. They keep on rotating consistently while transmitting the different types of signals through it continuously. The slip ring is comprised of two separate cycles, i.e., inner and the outer one. Whether it is an emotional cycle of the slip ring of it is about the outer cycle end, both of these are associated with some wires further creating the inlet and the outlet of the electric flow.

What is Through Bore Slip Ring?

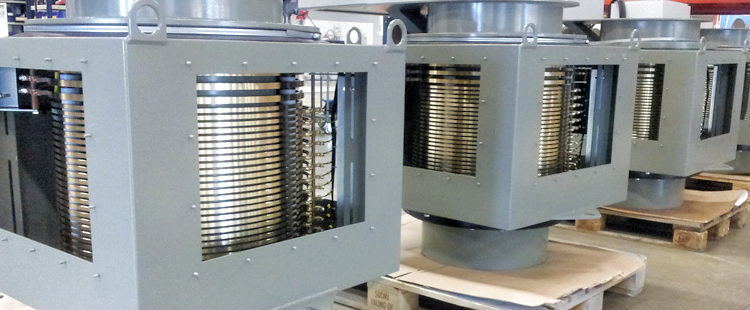

Through Bore Slip Ring is a kind of slip ring that is considered to be one of the essential parts of every electromechanical device. The Through Bore Slip Rings are the hollow shaft slip rings that offer a great path to the electrical and data connection to pass through a rotating assembly. The device is considered to be one of the useful sources of transmitting power and electrical signals, where continuity is supposed to be one of the significant aspects of this cycle. To ensure the proper functioning of the Through Bore Slip Rings, these consist in such manner that they go on continuous rotating without any failure.

Have you ever thought why Through Bore Slip Rings are called so? The answer to this question is quite easy to go through. It has bore, or hole in between the ring and that is why it is known to be Through Bore Slip Ring.

Through Bore Slip Ring is one of the essential parts of various automotive motor applications that is installed in the equipment as per on its rotation axis. Moreover, while enabling the installation procedure, the rotating joint of the Through Bore Slip Ring is supposed to be the transmitter of different types of signals for both fixed and unfixed structures as well.

As we have mentioned you earlier that the Through Bore Slip Ring includes a hole in it, the question arises here is that what does the importance of this hole here. Elaborating it for you in the most simplified way, this hole or bore present inside the slip ring is induced to allow valuable electrical and data connections without any interruption through a rotating assembly.

What are the main features of Through Bore Slip Ring?

Like does the other components, Through Bore Slip Ring owns some unique features that make it quite different and very special as well. Some of the main features of this beautiful construction are:

- Through Bore Slip Ring are usually designed to offer ease of flow of power and electrical current through it.

- The holes or bores in the Through Bore Slip Ring are usually constructed with the help of through bore hydraulic or pneumatic rotating shaft installation.

- The Through Bore Slip Ring includes fiber brush technology to add up more in the performance of an automotive motor.

- It improves the functioning of the automotive motor by providing an extended level of multiple points of contacts for each brush handle.

- The size of the bore or hole of the slip usually rings not same. It depends upon the dimensions and the performance of the automotive motor. Ranging from 3mm to 800 mm bore size, you can make use of these Through Bore Slip Rings in different types of components.

- Some off the Through Bore Slip Rings includes gold plated rings and gold allow brushes in them to ensure better performance of the device.

- Through Bore Slip Ring are the perfect combination of transmitting the different levels of power and signals through it.

Why use Through Bore Slip Ring?

Through Bore Slip Ring is one of the most critical parts of almost all of the automotive motors that include holes or bores in between it. It is one of the first applications present in the market that you can install to raise the rotation of devices on their axis. These rotations are usually made to pass out different signals through it. The Through Bore Slip Ring is one of the most important parts of projects like automated testing equipment, automated tools, automation equipment an much more. For improving the performance of your product, you need to look forward to various structural and technical parameters.

Moreover, if required you can also for the customization of Through Bore Slip Ring as well depending upon the requirements of the projects where they are going to be used. These types of components are used in places where continuation rotation is required along its axis to generate electrical and power signals through it.

The holes present inside the Through Bore Slip Ring is being used to provide clearance to the various mechanical and electrical components such as shafts, axial structures, rotary joints an much more. One can easily customize the preferred Through Bore Slip Ring to meet the basic requirements of the project.

To improvise the structure and performance of the automotive motor, Through Bore Slip Ring includes different conductor channels in between the limited radial space. The power of the Through Bore Slip Ring is being dedicated in the form or RPM and is directly proportional to the power of channel requirements. Moreover, the introduction of various features like the location of the hole terminal point connection and the number of conductor rings being involved in the structure decides the performance of the project. Through Bore Slip Ring are also being available as a differentiate component where mating brush block assemblies are being designed to offer power and electrical signals effectively.