While most people are familiar with torque converters, they are unaware of how it works. It is not easy to figure out how it works since the fluid is sealed inwards, and therefore it is not easy to see it working. However, two fan scenario can easily explain how it works. Imagine the two fans are facing one other, and one fun is turned on. The fan will blow the air on to the other fan blades making it rotate. Still, if the other fun is held, the first fan won’t stop spinning.

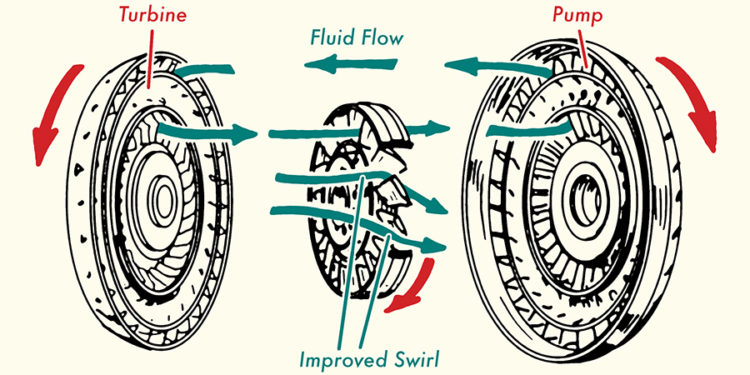

The above scenario explains how the hydraulic torque converter works. The converter has two “fans,” one known as an impeller, while the other is known as the turbine. The impeller is connected to the engine and covered with the front cover to make the converter’s outer shell. On the other hand, the turbine is connected to the transmission input shaft. Therefore, the vehicle keeps on moving as long as the turbine is in motion.

The torque converter does not use air but relies on an incompressible liquid medium, generally known as transmission fluid. There is a need to understand how a torque converter works as all automatic cars use it. Therefore, this article will explain how it works and why automatic cars need a torque converter.

Torque converter and clutch work in a similar manner. For a vehicle to move, the engine must be connected to rear wheels and disconnected to allow the engine to continue running even after the car stops. This can be done in two ways. First, a device can be used to connect and disconnect the engine to the transmission physically. The second is to use a transmission fluid such as a torque converter. It is located between the engine and the transmission.

Most people ask what components of the hydraulic torque converter are. Well, it comprises the pump, turbine and the stator. All these components work together in ensuring that torque converter transmits power.

1. The Pump

The pump in the convertor works like the centrifugal pump. As the converter rotates, the pump flung the fluid to the outside, just like how washing machine works. Flinging the fluid creates a vacuum drawing more water in the center.

2. Turbine

Then, the fluid is pumped to the turbine blades. As the turbine spins, the transmission also spins, making the car move. The turbine blades are tactically curved to ensure that the fluid changes direction before exiting the turbine center. This change of direction makes the turbine spin.

3. The Stator

The stator is situated at the center of the torque converter. Its work is to prevent the fluid from hitting the pump as this can slow down the engine. It then redirects the fluid, which returns from the turbine. In so doing, it prevents it from hitting the pump. Therefore, the stator is the component that increases torque converter efficiency.

In summary, the torque converter can be said to be a transmission fluid that facilitates the engine’s spinning without interfering with the transmission. It offers the force needed in moving shift transmission gears through the pressure from the automatic transmission fluid.

A dysfunctional or worn out torque converter is disastrous. The vehicle cannot operate since the convertor fails to pressurize the transmission fluid. This also means that the gears cannot function. It is recommendable for any vehicle owner to have a professional systematic vehicle check.

If it is used well, the torque converter can make your vehicle perform very well and improve its durability. Ensure that it is not tampered with and if there is any course of concern, ensure that you consult a professional for a check-up.